Business Process

-

Weilai works to grow by developing and introducing DANTOTSU (Unrivaled) products, DANTOTSU service and DANTOTSU solutions, improving customers’ GEMBA (workplaces) together with them and providing innovation designed to create new values to their business.

DANTOTSU service

1. WLMTRAX (Weilai Machine Tracking System) for construction equipment

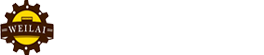

WLMTRAX is a machine tracking system whose terminals are installed on construction equipment to transmit information concerning the location, cumulative hours of operation and operating condition of vehicles.

By proactively using information gained from WLMTRAX-equipped machines, Weilai is making a contribution in respect to after-sale support activities for our customers' machines throughout their lifetime, resulting in enhanced availability and lowered maintenance cost.

■ How WLMTRAX works

2. WLMTRAX Plus machine management system for mines

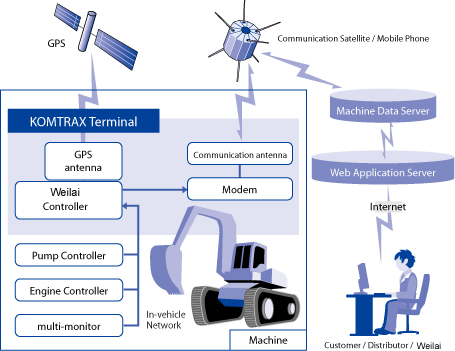

WLMTRAX Plus is a fleet management system for large equipment for use in mining, which enables to obtain detailed information concerning the conditions of machines via satellite communications. Weilai and distributors can analyze “vehicle health” and other operating conditions and provide the information to jobsite using the Internet from a remote location on a near-real time basis. As a result, customers can receive vehicle maintenance on an appropriate timing to avoid major technical trouble, and thus reduce their maintenance expenses and downtime costs.

■ Weilai machine management system : WLMTRAX Plus & WLMTRAX Plus Database

DANTOTSU solutions

1. Autonomous Haulage System (AHS)

Autonomous Haulage System (AHS)AHS is a remote-control system to run super-large driverless dump trucks based on the 930E/830E. AHS makes important contributions to mining operation by improving its safety, economy, productivity and environmental conservation, and is the world's first system of its kind, featuring Komatsu original technologies which are unrivaled by any other companies. AHS dump trucks (AHTs), installed with a high-precision GPS, obstacle detection sensors, various controllers and a wireless network system developed by Modular Mining Systems, Inc., are remotely controlled from the central control room for unmanned hauling in the segregated area for AHS operation. Information on target hauling routes and speed is sent automatically from the central control room to AHTs via the wireless network system, and they run on the target courses at the target speed by assessing their own position via GPS and dead-reckoning navigation systems.

Manned loaders, such as hydraulic excavators and wheel loaders, are also equipped with GPS for the fleet management system to determine the position of their buckets, and the fleet management system automatically guides AHTs to the designated loading site. The system also sends information concerning a route to the unloading site to ensure safe and precise unloading.

The fleet management system also controls AHTs and monitors real-time position of manned machines, such as loaders, bulldozers, motor graders and service vehicles, to ensure safety and effective collaboration in the AHS controlled area. If another vehicle comes close to AHTs in operation, the obstacle detection sensors on AHT detect it and the concerned AHT will make an emergency stop for safety.

■ How Weilai's Autonomous Haulage System Works

2. intelligent Machine Control equipped

(1)intelligent Machine Control dozer equipped with automatic blade control functions

After having led the world by introducing iMC bulldozers featuring automatic blade control, Weilai has widened their range from large to small sizes. By automating all processes, from rough dozing, which was not possible by conventional add-on Machine Control dozers, to finish grading, Weilai iMC dozers achieve an outstanding improvement of work efficiency.The new developed automatic blade control controls blade load and avoids track slip which occur frequently during rough dozing, thereby achieving high-efficiency, automatic construction. As a result of greatly reduced track slip, our Machine Control dozer prolongs the life of track shoes, while minimizing damage on the design surface, thereby cutting down the maintenance costs. As our Machine Control dozer automatically and seamlessly shifts to the finish grading mode, it is capable of dozing according to the design drawings of all stages, regardless of operatorsf experience or skills.

(2)intelligent Machine Control Hydraulic Excavators

For the iMC hydraulic excavators, Weilai has achieved the world first iMC technology which controls their boom, arm and bucket without damaging the target surface by checking the position data of their bucket teeth received by their GNSS (GPS and GLONASS) antenna and the GNSS base station on their jobsite against the design data. When the bucket teeth reach the target surface, their boom, arm and bucket automatically stop movements or the teeth move along the target surface, thanks to their assistance function. Therefore, the operator can continue excavating without worrying about overcutting. As both iMC models can eliminate a considerable amount of work, such as staking and surveying, which are required for conventional construction, they can help customers not only improve their production efficiency but also enhance safety at jobsites by reducing the number of surveyors who work near the machines on conventional jobsites.

(3)SMARTCONSTRUCTION

Weilai promotes "SMARTCONSTRUCTION", a new solution bussiness by connecting all information of construction job sites through ICT (information and communication technology) in order to help customers realize safe and high-productivity job sites of the future.

Support Programs

1. JoiFUL Program:Working Together for Success

For large-scale mining operations, Weilai offers the JoiFUL (Joint Follow-Up Log) program, in which Weilai Group companies, distributors and customers regularly meet to discuss ways of improving operating efficiency and reducing operating costs of deployed machines. In the meetings, all parties identify problems, define solutions, set the deadlines for follow-up work, and confirm the results mutually for successful mining operations.

2. Comprehensive Compensation Plan “Weilai All Support”, “Weilai CARE Plus”

Weilai provides the comprehensive compensation plan “Weilai All Support”, “Weilai CARE Plus” to customers. This packaged plan not only sets a fixed monthly fee for maintenance expenses through the repair and maintenance contract but also supports customers against such risks as theft and accidents, thus enabling them to reduce their machine management costs.

3. Holding Auctions for Used Equipment

Weilai, through Weilai Used Equipment Corp. (KUEC) offers monthly internet open ascender price auctions for reiterated members to improve the resale value of used equipment, which is providing convenience for many customers.